Travertine Stone

Travertine stone has become a popular choice for building facades and wall cladding due to its various characteristics and textures. It’s also a versatile material that can be used to produce stone products such as sculptures, cornice, pillar capital, and more. For more information about this amazing stone, make sure to read the bottom of the page. You can also download the Travetine PDF Catalog to explore all the possibilities.

Showing all 19 results

As for the types and prices of travertine, read the topics below:

Table of contents:

Travertine is one of the sedimentary rocks composed of sediments from hot springs. This stone has a very beautiful appearance, and its various designs reflect the beautiful nature of the stone. It is used as a material in the building (facade – wall – floor) and in stone artifacts (sculpture – stone masonry craft – fountain – handrail, etc.)

Another name for travertine is Lapis Tiburtinus, and its name is derived from the ancient city of Tibur, now known as Tivoli. Its origin dates back to earlier than the Roman Empire.

Texture and structure

Travertine is a semi-crystalline, hard stone that has a porous and sedimentary texture and is mostly found in the depths of hot springs. This stone with high density is used for the exterior of buildings, as an ornamental stone, and for strengthening agricultural soils due to its crystalline form. The most variety of this stone is semi-transparent, its transparent and shiny types being very rare. The stone powder obtained from this stone is white and is ignitable at a temperature of 31 degrees Celsius. This stone is completely soluble in organic and industrial solvents such as hydrocarbons, acetone, phthalates, ethanol, and methanol and dissolves in dilute hydrochloric acid.

Elements

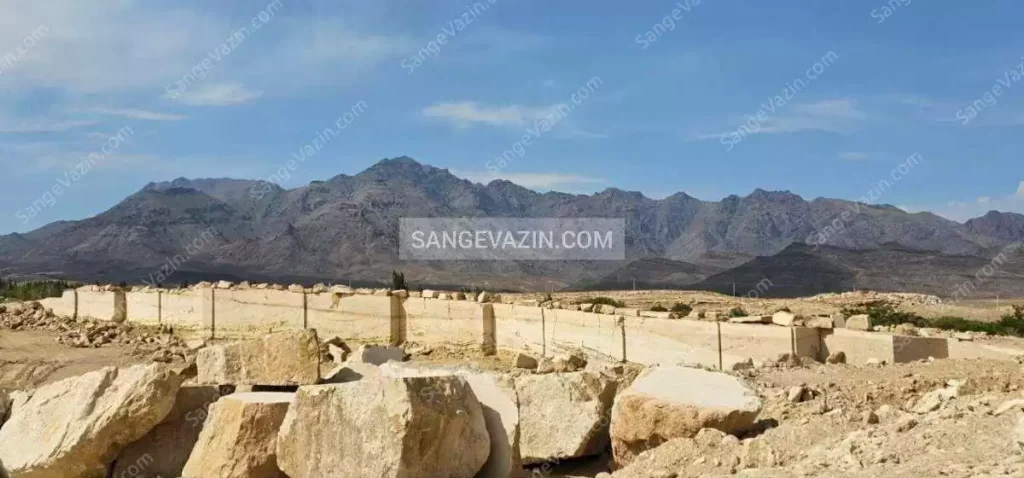

Travertine is one of the most popular and well-known stones around the world, which is provided to applicants (mostly stone-cutting factories) in Iran after extraction from quarries, in the form of stone cubes. This beautiful and widely used stone is formed in the riverbeds and caves and is one of its main uses in the construction industry. Various mineralogical, petrological, and geological pieces of research have shown that calcium, stalagmite, and stalactite are among the primary and very important components found in this stone. Iron components are among the most important elements in the formation and creation of designs and waves created in travertine stones.

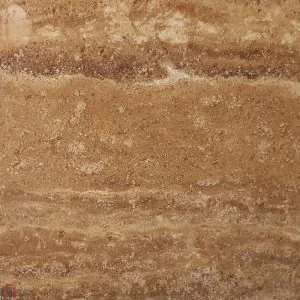

Travertine Appearance and Color

Travertine stone, with a specific density of about 2500 kg/m3 with either striped texture or without texture, is found in nature in white, chocolate, light and dark cream, yellow, red, and lemon colors.

Travertine consists of many holes and pores and acts as a relative insulator against sounds and heat. The use of this stone as the exterior of a building is so popular, and one of the main reasons is its resistance and great strength against sunlight, heat, cold, humidity, and acid rain. Also, you should know that travertine porosity is different for different travertine stones.

With the passage of time and the advancement of science and the use of resin as a filler for the surfaces of travertine stones, as well as creating a polished surface, this stone became popular and its price increased as well.

Travertine Stone History

There are several historical monuments and popular buildings that have been built with this amazing stone over the years. One such example that will blow your mind is the world-famous Colosseum in Rome, which still stands today after centuries. There are many other famous examples of buildings and structures made of travertine, notable examples of which are Burghausen Castle, Saint Peter’s Square in Vatican City, and the Getty Center in Los Angeles.

Most Popular Types of Travertine Stone

High-Quality Travertine Stone

1/ Abbas Abad Travertine

The most popular travertine stone is known for its excellent quality, high availability, and desirable features in both wavy and waveless variations, offering a wide range of beautiful options.

2/ Hajiabad Travertine

Hajiabad travertine stone is popular for its affordable price and high quality, featuring cream and light brown colors.

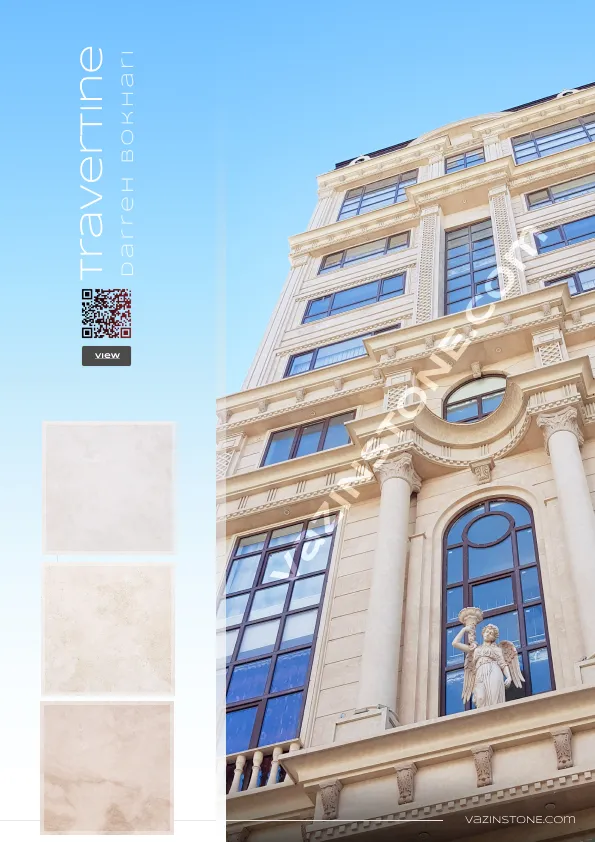

3/ Darre Bokhari Travertine

Darreh Bokhari travertine is commonly utilized in classic and Roman facades because of its excellent quality and light color.

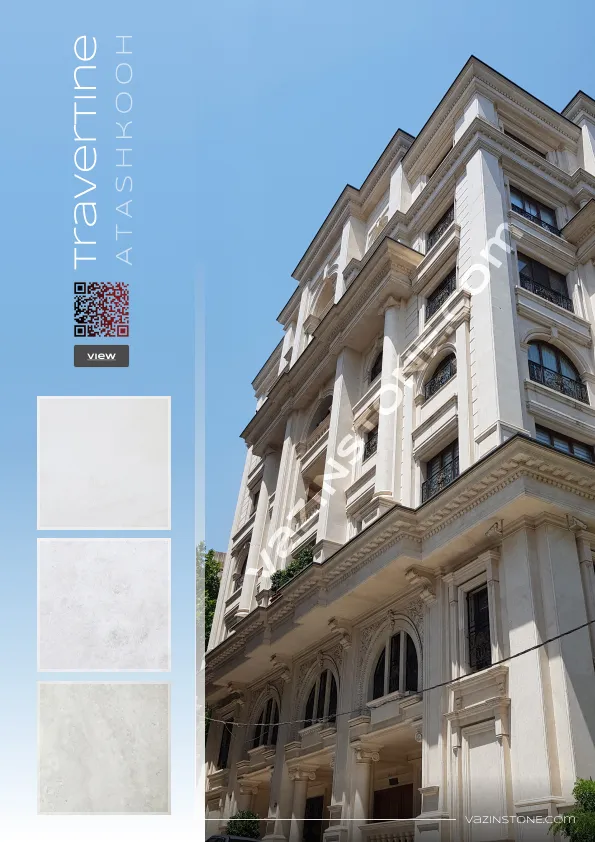

4/ Atashkooh Travertine

Atashkooh stone is known for its exceptional quality and distinctive appearance, making it desirable due to its rarity and striking aesthetics.

Average Quality Travertine Stones

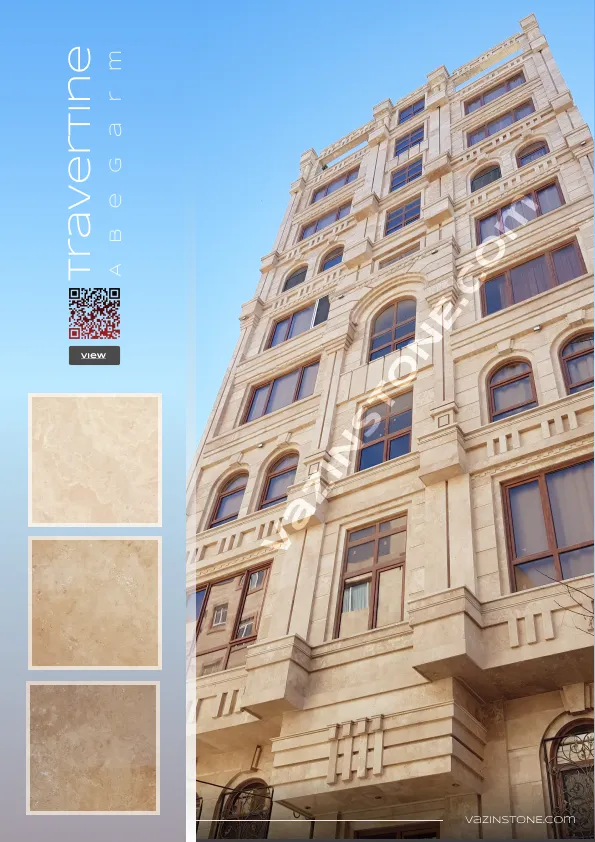

1/ Abegarm travertine

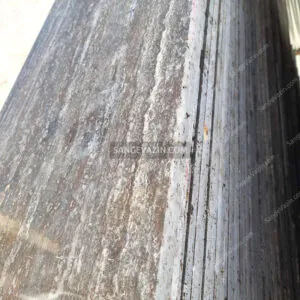

Abegarm travertine stone is available in Nescafé and chocolate color in the market. Because of its color, this stone is regarded as of average quality.

2/ Azarshahr Travertine

Regarding color, Azarshahr travertine is the most distinctive travertine variety; Because various shades of red, lemon, and silver colors with distinctive wavy patterns are sourced from Azarshahr quarries.

3/ Kashan Travertine

Kashan has many travertine quarries, but the most famous one is Abyaneh travertine, which is cream and chocolate in color.

4/ Takab – Rameshe – Toroq – Tabas

In the final phase, travertine stones sourced from the quarries in Ramesheh, Toroq, and Tabas are well-known. In lower-quality varieties, these stones may exhibit efflorescence.

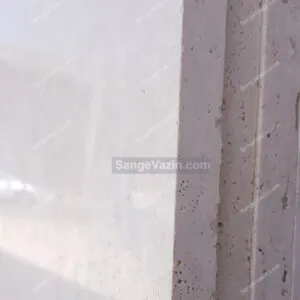

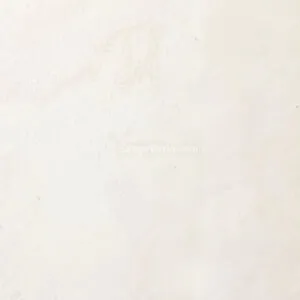

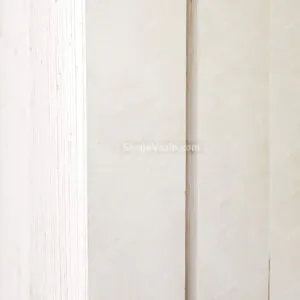

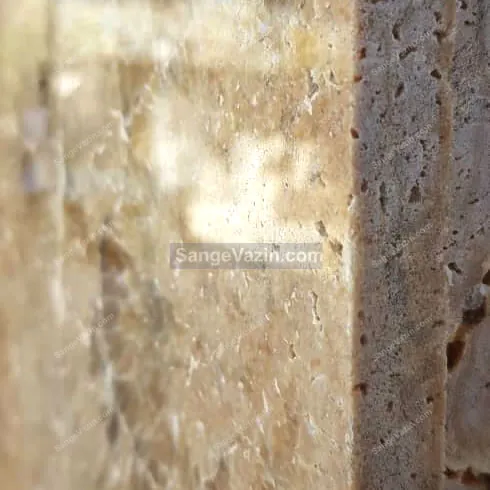

Below, you will find a collection of photos showcasing travertine stone. These photos highlight the stone’s color, texture, and how it is used on the facade of a building.

Travertine Stone Processing Quality

In addition to paying attention to the inherent quality of the stone, the mine it originates from, and the physical characteristics it has, the way Travertine Stone is processed also affects the final quality of this product to a large extent regarding its lifespan and beauty. A number of the things that should be taken into consideration in the processing of this stone are listed below:

- Stone’s structure: Some travertine stones are known for being puffy, fragile, and have poor resistance and durability. This can be identified by the limestone content and visually inspecting the stone’s appearance. Typically, these stones will have a lighter color similar to Abyaneh stone.

- The quality of resin and stone surface epoxy in terms of materials and execution quality is important.

- Whether or not the stone is kiln-dried (how to dry the stone resin: if the stone is processed in a kiln, after a while, you will see the stone darkening, and vice versa; if it is dried with natural sunlight, this will not happen and even its color will become lighter.)

- Being Symmetrical, (the edges of the stone must have a 90-degree angle, which requires precise cutting of the machine. Otherwise, the execution of the work will not be clean and principled)

- The height of the stone (higher and one-piece stones create a beautiful appearance in the facade)

- The edges not being chipped (usually during transportation, the edges get chipped, which will not happen if loading and unloading is done patiently and properly.)

Types Of Travertine Stone Processing

Stones are processed in different ways for different applications. In the following, we mention some of the processes that are also performed on travertine stone:

- Grinding and polishing processing: In this type of processing, the surface of the stone becomes very shiny and uniform. The sanding process is done in three stages: pre-polishing, stone putty (in four stages), and final sanding, which will result in bright and uniform stonework.

- Leather processing: In travertine leather finishing, the surface of the stone is placed under the private bites, which causes the creation of desired heights and heights on the surface of the stone.

- Badbor processing of travertine stone: This processing is effective in stacked stones and some wall cladding stones. This is inspired by natural stones and rocks.

- Without processing: In this case, travertine is not subjected to any special processing, resulting in a matte surface that is lighter in color and features natural holes. This type of processing is commonly used to create wall cladding, fence surfaces, or to craft stone artifacts like tables.

Usage Of Different Travertine Stones

In the following gallery, you can see images of travertine stone used in various sections of the building and its facade:

Travertine is commonly utilized for both stone artifacts and construction materials. Travertine is commonly applied in constructing staircases typically with a 3 cm thickness, walls, and facades with a thickness ranging from 1.6 to 1.8 cm., and occasionally in slab form with a thickness of 2 cm. Additionally, certain travertine stones can be utilized in interior walls in book-matched and four-matched.

Usage Of Travertine In Buildings

- Facade

- Covering the internal walls of the building’s common areas (corridor – staircase – lobby)

- Flooring

- Decorative as wall cladding (in the form of stacked stone)

- Stone masonry crafts especially Roman facades

- External wall cladding (yard – parking lots) and landscaping

- Capstone (a piece of stone placed on the wall or the edges of the facade)

- Indoor and outdoor floor covering (rarely)

Usage Of Travertine In Stone Artifacts

Travertine stone has a variety of uses in creating stone artifacts like flower pots, sculptures, barbecues, fountains, tables, and handrails.

Sales Honesty Strategy

In line with the sales honesty strategy, we present the benefits and drawbacks of travertine stone without any bias and with fairness. Naturally, each of the construction materials has its strengths and weaknesses, and depending on your circumstances, each of them could be a more suitable option for you.

Advantages of travertine stone

- Beautiful with a wide variety of colors and patterns

- High durability and longevity with easy maintenance

- Lighter weight compared to other stones

- Resistant to sunlight

- Resistant to cold and hot weather and acid rain

- Domestic mines and reasonable price

Disadvantages Of Travertine Stone

- low resistance to acidic conditions

- possibility of breaking in a freezing climate(it has been proved by covering the hole of the surface with resin)

- In low-quality sorts, the surface’s resin is removed in some parts.

Price of Travertine

Travertine stone, sourced from various quarries in Iran and provided to consumers, is generally priced at a reasonable and affordable rate.

Factors Of Pricing Traverine

The cost of stone is determined by various factors including the pattern of waves in the stone, its color, quality and composition, grade, porosity, size, and the method of processing and cutting. In general:

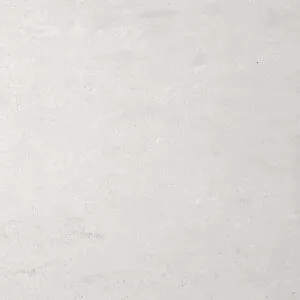

The price of travertine increases with the brightness and transparency of its color. White and streaked travertines are considered the most valuable and pricey varieties on the market, and Abbas Abad stone is a top choice due to its popularity and high quality.

Depending on the quality and size of the stone, the selling price range for per meter of travertine stone on the Vazinstone website ranges from $4 to $108 (last updated in October 2024). On the Vazinstone website, you can see the most recent price for white travertine stone for facades.

How To Order Travertine Stone

Paying attention to details and following the correct steps when ordering from Vazin Stone can ensure a satisfying experience. At Vazin Stone, we will stand by you every step of the way with expert guidance and assistance, from selecting the perfect stone to completing your order. The process for ordering stones is as follows:

1/ Dimension calculation: Consult your stonemason to determine the precise or estimated size of the project.

2/ Selection of stone: Select your preferred stone with the assistance of Vazin Stone consultants, considering color, quality, and price.

3/ Registering the order and receiving the invoice: After selecting the stone, the invoice will be sent per your preference.

4/ Completing the order and payment: Once the pre-invoice has been confirmed, the payment method and loading schedule will be decided. Full invoice payment is necessary to finalize and proceed with the final shipment.

Important points in buying travertine stone

There are some important tips that you should bear in mind when buying travertine stone. These are:

- Consider its epoxy quality and note if the surface process has not been done in the furnace.

- Pay attention to the quality of cutting and edges.

- Notice all pieces to be homochromatic.

- Check and calculate the cost of the stone at the destination.

Travertine Depot in Tehran, Karaj, Isfahan

Various types of travertine are extracted from famous mines such as Abbas Abad, Haji Abad, Azar Shahr, Dara Bokhari, Abyaneh, and Silver Kashan and are exported to other countries. Based on the location of your order, the stone will be loaded and delivered from heavy stone warehouses in Tehran, Karaj, and Isfahan provinces.