Types of granite stone finishing

Stone finishing is a crucial phase in stone production and processing. Since various building stones have specific uses in different building parts, stone surfaces must be finished accordingly based on their purpose. For example, some areas require a rough surface to prevent slipping, while others need a glossy surface. Sooran black granite Natanz is one of the granites that have undergone various polish and finishing processes, offering 24 types of finishing. This article explores the different kinds of black granite finishes.

You can learn more about granite finishes in the article below:

Table of Contents

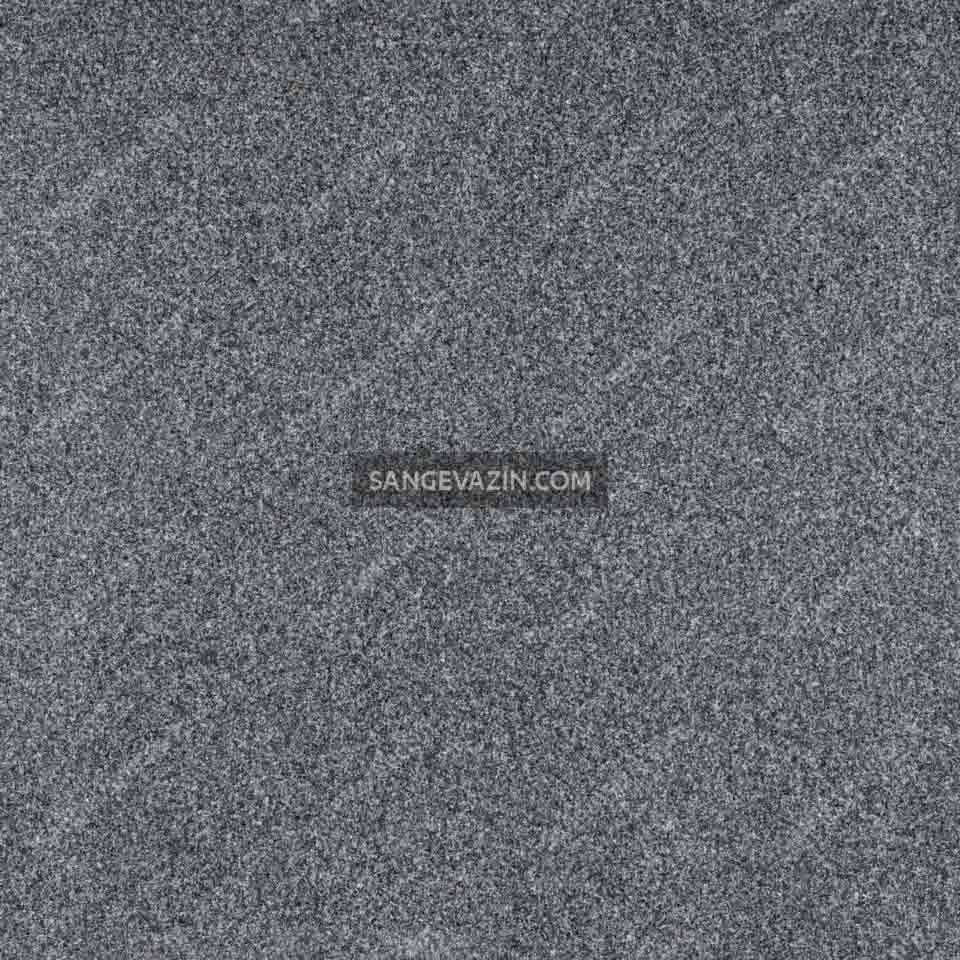

1/ Polished

The stone’s most common and most used finish is the polished finish. In this finish, the stone’s surface becomes completely polished and shiny. The most common use of this finish is on stairs, floors (generally interior spaces), and walls of buildings, and it should be avoided for use where it is possible to get wet and slippery.

2/ Honed

The stone’s surface is smooth but lacks a shine or light reflection due to its honed finish. This finish is known for appearing more natural and less slippery compared to polished surfaces. Additionally, the stone’s color appears lighter with a honed finish.

3/ Flammed

Granite stones with a strong resistance often get this finish. In the flammed finish, the stone’s surface is heated by a torch with a low flame, creating a rough surface that prevents slippage. This finish can be used on the floor of the outside area and surrounding the stairs and pool.

4/ Leather flammed and flammed brushed

For a natural and classic look, leather diamond-tipped brushes finish uneven and unpolished stone surfaces. Because of its friction, this type of finish is perfect for flooring, outdoor stairs, swimming pools, sidewalks, bathroom floors, and even kitchen countertops.

By painting the flame-finished stone with special epoxy paint in 3 stages, performing the thermal stabilization process in the oven after each step, and finally removing the stain left on the surface, it is possible to achieve a colored leather-flammed finish.

5/ cut

Producing parallel or diagonal grooves on stone surfaces is called a “cut finish”. The various types of this finish are outlined below:

Polished cut

Creating parallel grooves on polished stone is known as a polished cut finish. This finish gives the building’s facade a stunning appearance.

Irregular cut

The finish of the stone has an irregular cut with grooves that create an eye-catching effect on the tiles.

Irregular sandblast cut

The irregular sandblast cut involves creating uneven grooves on the stone tiles while adding tiny abrasive particles to smooth out the edges of the grooves and ensure consistent coloring of the tiles.

Broken cut

To get a broken-cut finish, make consistent cuts on the stone and break it with a hammer. It’s commonly used on building facades and fountains.

Sandblast broken cut

“Sandblast broken cut” is a stone finish with softer edges and protruding indentations, resulting in a uniform color.

Hammered cut

We achieve a rough surface after cutting by using a bushhammer with diamond-tipped brushes. This process creates a visually appealing stone appearance and is often used in the design of fountains and villa facades.

Flammed cut

Creating parallel grooves in flamed stone preserves its natural characteristics while providing a high level of friction, making it an excellent option for sloping parking lots.

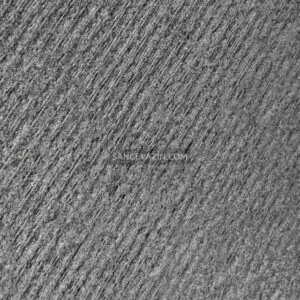

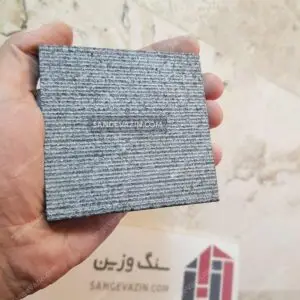

6/ Scratched

A scratched finish on stone is achieved by making small, shallow, parallel grooves, which creates a rough texture.

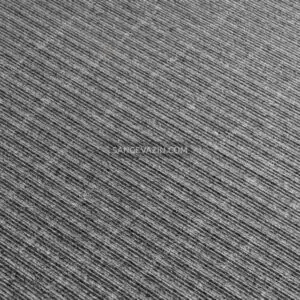

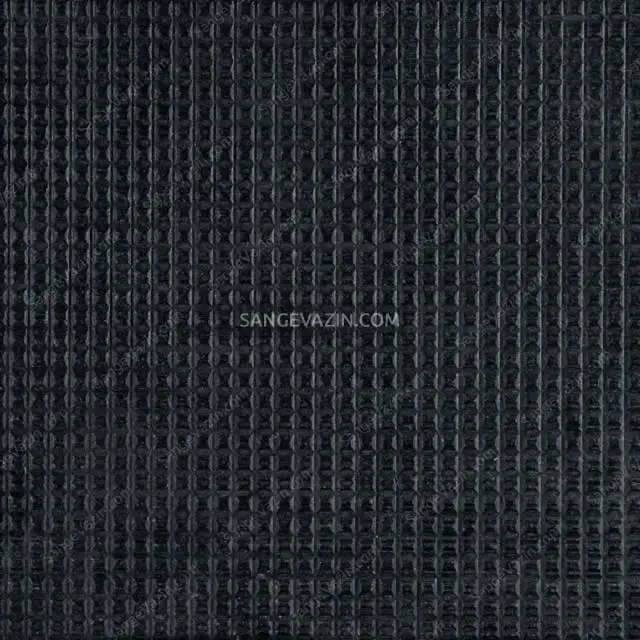

7/ Cotton

The cotton finish stone is achieved by creating horizontally and vertically perpendicular grooves at equal intervals. This results in a surface with high friction and a visually appealing appearance.

Publish on:

July 21, 2023

Quality guaranty

Fast delivery

Price guarantor

Customers Club